Tunnel T4 on the S7 Lubień-Rabka Zdroj ![]() Per la versione in Italiano: https://www.stradeeautostrade.it/attrezzature-e-componenti/la-galleria-t4-sulla-superstrada-s7-lubien-rabka-zdroj/

Per la versione in Italiano: https://www.stradeeautostrade.it/attrezzature-e-componenti/la-galleria-t4-sulla-superstrada-s7-lubien-rabka-zdroj/

Project´s general information

The S7 Lubień-Rabka Zdrój roadway through the Voivodato Malopolskie region is divided into three sections. The second – the most expensive and time-consuming section of the investment – is being built under the mountain Mały Luboń. The two-chamber tunnel will be over 4 km long in total.

The task included the preparation of the complete tunnel design for the concreting of the fixed tunnel lining using the austrian method.

Each chamber will carry traffic in one direction, each one covering 2.06 km. The tunnel will have emergency passages between the chambers, two portals, the fan room, as well as the complete equipment and technical infrastructure.

For the construction of the tunnel it was necessary to drill about 1922.4 m of the left tunnel and about 1919.6 m of the right tunnel. Other parts of it are being carried out inside an excavation that will be covered, once the works are finished.

The excavation of the tunnel began with the right-hand northern portal at the beginning of March 2017, and the completion of the entire tunnel will be completed by the middle of 2021.

The project’s description

The project of the TMK carriage for the fixed lining was carried out in the MK system with the application of TMK elements.

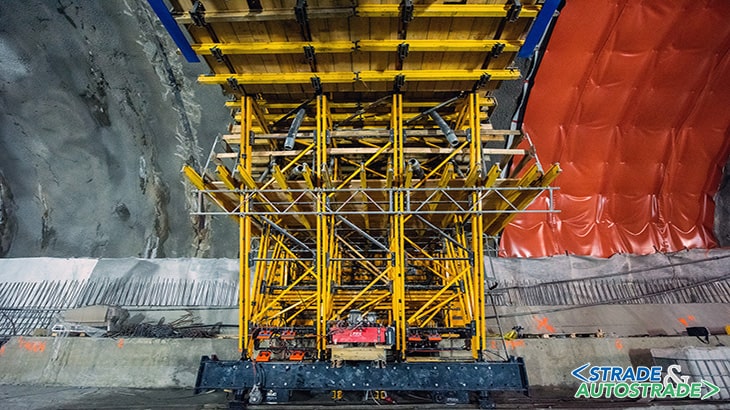

The main structure of the carriage is a frame made up of MK braces, as well as TMK plates and nodes and special TMK elements distributed every 1.5 m. The structure can be divided into several main parts.

The frame support is a beam made of DUPN profiles that guarantees the support of the loads that are transmitted to the floor during the concreting process and is equipped with wheels to move the carriage.

The support structure is made up of the V frames, on which the main trusses are mounted in two rows. In addition, the wing structures are suspended from the TMK nodes, and above the V frames there are special individually-made structures for the formwork of the fixed lining cornice.

The structure of the carriage is completed by the main brace of the lining, with a geometry that is adapted to the geometry of the tunnel. The entire carriage is covered with 5 mm thick covering sheets, supported by omega steel profiles, which are attached to the MK braces by means of omega clips.

The carriage is lined with inspection windows to control the pouring of the concrete mixture and diaphragms for the distribution of the concrete mixture. The inspection tubes are located in the lining concavity and allow the correct filling of the section to be checked.

Complementing the complete equipment of the carriage are the pneumatic vibrators that form a congruent system, fixed to the MK braces. Another factor that guarantees smooth handling of the carriage is the hydraulic system.

The entire system is supplied by the FPT pump and allows for the hydraulic release of the wings, the levelling of the carriage and its displacement. In addition, during the concreting process, the wings are anchored to the previously constructed floors by means of DW26 tie rods. The carriage is equipped with a communication and operation system using VM beam platforms and F4 ladder system.

The adopted solutions

The design of the carriage needed to be adapted to a complex tunnel geometry, especially in the area of the cornice under the floor slab. A special cornice plate was prepared for this purpose, allowing the loads from the concreting to be supported and allowing efficient formwork removal without the need for the use of hydraulic systems. Pre-fabricated sheets of the lining were also applied to the carriage to ensure a good surface finish of the concrete.

The assembly of the carriage on-site was the responsibility of Ulma (www.ulmaconstruction.it). The assembly differed from the normal assembly of the tunnel carriage as it took place inside the tunnel, the access to the station was carried out through the evacuation passage, which was smaller than the tunnel.

Therefore the division of the assembly into stages had to be adapted to the transport possibilities of the elements through the evacuation passage. The main structural elements of the carriage were prepared beforehand in an assembly station.

The assembly was divided and carried out in the following stages: first the DUPN bottom profile was assembled with cylinders and wheels. Then the V-frames were assembled in tandem and stabilised accordingly. Then the special cornice plates were mounted.

In the assembly station, the upper truss was prepared with the complete lining and equipment, and then this whole set was mounted on the carriage by two Manitou vehicles. The last stage was the placement of the pre-assembled wings of the carriage with lining on the tunnel floors and the placing of the carriage on them and the fixing of the wings to the carriage by means of D40 bolts.

Technical data

- Contracting Authority: Generalna Dyrekcja Dróg Krajowych i Autostrad (Polska)

- General Contractor: Astaldi SpA

- Duration of the works: In progress

- Sumbmission date: March 5, 2020

- Completion date: In progress

Tunnel T4 on the S7 Lubień-Rabka Zdroj ![]() Per la versione in Italiano: https://www.stradeeautostrade.it/attrezzature-e-componenti/la-galleria-t4-sulla-superstrada-s7-lubien-rabka-zdroj/

Per la versione in Italiano: https://www.stradeeautostrade.it/attrezzature-e-componenti/la-galleria-t4-sulla-superstrada-s7-lubien-rabka-zdroj/