Absolute protection ![]() Per la versione in Italiano: https://www.stradeeautostrade.it/cementi-e-calcestruzzi/la-protezione-totale-del-calcestruzzo/

Per la versione in Italiano: https://www.stradeeautostrade.it/cementi-e-calcestruzzi/la-protezione-totale-del-calcestruzzo/

The urban transformation interventions and building development continuously growing over the years, together with the higher intensity of weather events, are leading to an increase in the supply of rainwater and draining systems by modifying their hydraulic and hydrogeological schemes.

Increasingly, regional and municipal regulations in accordance with the european Directives require to control the incoming water to the sewers – allowing their disposal through natural infiltration into the ground.

No pollution occurs because the rainwater is separated first, and then pumped to the public sewer or the sewage plant at limited and constant range, through specific deoiling treatments or chemical-physical plants.

These interventions involve the installation of one or more basins for the hydraulic invariance. These storage tanks are able to act as a hydraulic shock thanks to the temporary storage volumes of outflows and the reduction of the infiltration during intense rain, as they temporarily retain the range intercepted by the waterproof surfaces.

The courts affected by the meteor shower must be properly prepared to act as conveyors with interventions aimed at cleaning up the rainwater coming from roads, highways, transit areas, petrol stations, and car parks – polluted mainly by the losses of parked cars or passing with the presence of mineral oils, sands and soil.

Coprem produces retention basins of all sizes and types, taking advantage of the modularity of its box culverts, which can be composed like building bricks to carry out the most challenging projects.

Such as the construction of the Pedemontana Lombarda motorway, the regulation of the court of a multinational company, the redevelopment of the central square in a big city, the recent Charles de Gaulle Express railway connecting the airport to the center of Paris, and the intervention to the Genova San Giorgio bridge – always with a significant advantage in the construction of the project.

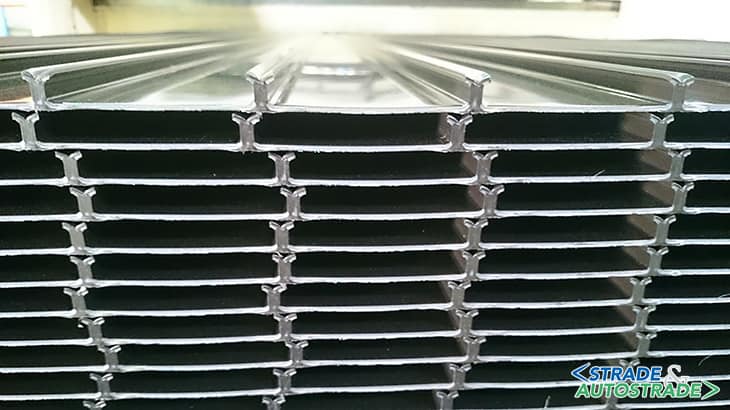

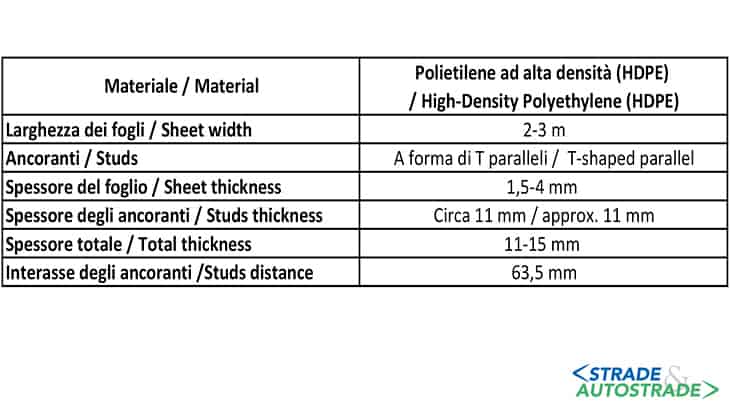

The protection system guarantees the absolute waterproofing even in the case of seismic landslides or settlements causing large cracks – thanks to the elongation at break property of more than 600% of the HDPE T-Grip Lining System, used and marketed exclusively by our Company throughout Europe.

Coprem’s modular system offers almost infinite volumetric capacity and different internal surface protection systems. The most used are the basins with the interior surface fully lined with High Density Polyethylene sheets and the Welded Joint patent – with the HDPE sheets only on the joints. Both solutions guarantee an absolute waterproofing – ensured by radiography and joint welding certification.

Coprem’s Technical Department can offer a wide range of turnkey design solutions according to various needs, including the ability to apply the HDPE T-Grip liner on in-situ castings – maintaining the same waterproofing, hydraulic sealing and protection guaranteed for the precast modules.

The turnkey service of Coprem Service Department once again makes the difference. A single interlocutor to design, produce, lay and weld with the related seal guarantee certifications, to have always the right solution with the best value for money.

In the case of basins which must be cast in-situ, Coprem’s Technical Department and Coprem Service Department are able to study in detail the application of the HDPE lining on the formworks. The Company can subsequently perform the welding, guaranteeing the waterproofing requirements of the project are met.

Advantages of retention basins

The collection is wide, and can meet every need:

- no infiltration inside the basin;

- resistance to chemical agents and to abrasion;

- elasticity (break elongation greater than 600%) with deformation without breaking and compensation of any settlements of the basin without leaks;

- ability to place the lining system even for in-situ castings;

- high adherence of the liner to the concrete (resistance to detachment beyond 38,000 kg/m2);

- maintenance over time of project characteristics (more than 100 years);

- self-cleaning thanks to limited internal friction;

- validation of the welding on the joints with a holiday detector to ensure the perfect hydraulic sealing.

![]() Per la versione in Italiano: https://www.stradeeautostrade.it/cementi-e-calcestruzzi/la-protezione-totale-del-calcestruzzo/

Per la versione in Italiano: https://www.stradeeautostrade.it/cementi-e-calcestruzzi/la-protezione-totale-del-calcestruzzo/