Side by side in the quest of sustainability and circular economy ![]() Per la versione in Italiano: https://www.stradeeautostrade.it/materiali-e-inerti/fianco-a-fianco-nella-ricerca-di-uneconomia-circolare-e-sostenibile/

Per la versione in Italiano: https://www.stradeeautostrade.it/materiali-e-inerti/fianco-a-fianco-nella-ricerca-di-uneconomia-circolare-e-sostenibile/

Cams Srl was founded in 2001, inheriting 40 years of know-how thanks to the acquisition of the TEM brand, a producer of waste crushing plants since 1964. Cams (https://www.camssrl.it/en/p/2/azienda.html) has been always active in research and development and attentive to meet the needs of the market with innovative solutions and exclusive patents. In recent years, Cams has dedicated part of its research to the sector of the asphalt recycling.

The ability to understand the potential of the sector before the competition, gave the Company the opportunity to start a longterm project in collaboration with Alma Mater Studiorum – University of Bologna for the development of its technologies, leading it today to be the world’s leading technology for asphalt recycling.

Among the technologies developed specifically for the treatment of asphalt, in the last year was born also a secondary crusher, CTR 1200, equipped with teeth specifically designed to create a product of the highest quality maintaining 100% of the bitumen contained in the recovered material.

Among other innovations, Cams has recently patented at international level a system of mechanical fingers, the so-called pushers that allow to introduce into the grinding vents not only the milled but also the asphalt slabs.

The task of the pushers, equipped with knives on their ends, is to dimensionally reduce the slabs and increase the grip capacity of the counter-rotating shafts, keeping the material inside the working angle of the teeth, and also allowing the recycling of that part of the material that would otherwise be landfilled.

The meeting before the breakthrough

Varia Costruzioni has moved its first steps in the world of asphalt producing bituminous conglomerates. Over time, thanks to the direction taken by Europe towards a circular economy, and understanding the enormous need to recycle the raw material, the Company developed its first approach to asphalt recycling, using an existing plant located in one of its production sites, which, until then, had been dedicated to the recycling of aggregates.

Once evaluated the potential of this new activity, and given the value and the importance that the Company places in the experimentation, Varia Costruzioni through Varia Versilia Ambiente activated a collaboration with the University of Pisa to refine the process of reuse of the milled asphalt in the bituminous conglomerates.

The research in this field has led Varia Versilia Ambiente to look for potential partners that could support it in the optimisation of the milled asphalt recycling process. It was at this point that Varia Versilia Ambiente met Cams.

Varia already knew Cams by the common participation to several trade shows such as BAUMA and ASPHALTICA, and after hearing the positive opinions of customers who had already turned to Cams, Mr. Varia had no doubt about the choice to rely on the latter as a strategic partner for the development of his activity.

Noticing the growing global focus on waste recovery, and the particular attention to the global economic situation, which no longer allows high expenses in the absence of certainties as to the return on investment, Cams has always been a step forward in the belief of wanting to improve process efficiency by developing more and more cutting-edge technologies that bring, at the same time, to the production of materials of superior quality with a certain economic return of the purchase of the plant.

With machines that operate the disintegration of the material, Cams is able to recover 100% of the bitumen that was instead dissolved due to the breaking of the aggregate by the traditional crushers.

Mr. Varia himself tells the reasons that prompted him to choose Cams as supplier of a specific technology for the treatment of RAP (Reclaimed Asphalt Pavement): “The ability of the UTS line of Cams to disrupt the material, bringing the particle size curve back to parameters similar to those of the pre-aggregation and, at the same time, to leave virtually unchanged the bitumen content on the inert, make the grinding process much more efficient than the traditional mixing with hammer mills”.

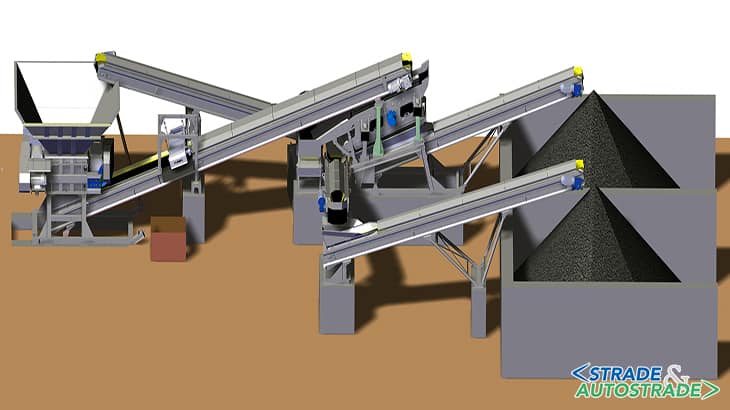

Cams has specifically studied and developed for Varia Versilia Ambiente a system solution that includes a primary crusher UTS 1000-2 and a two-storey screen UVS 25/2 which respect, also in shape and size, the spaces of the customer.

The plant provides the possibility to obtain two finished products of different grain size without producing any waste. Through a conveyor belt system, the oversize material coming from the screening machine UVS 25/2 is in fact reintroduced inside the hopper to be further processed in order to obtain the required size.

The high efficiency of the plant both in terms of mixing and screening, allows Varia Versilia Ambiente to put the material directly into the production cycle of the bituminous conglomerate, respecting the percentages allowed by the current standard UNI EN 13242 “Aggregates for unbound and hydraulically bound materials for use in civil engineering work and road construction” and complying with the quality standards imposed by the CE marking.

A solution for every need, respecting the environment

Not only Varia Versilia Ambiente, but also other 800 customers around the world have chosen Cams for the installation of their own plants. Eng. Andrea Trentini, Commercial Director of the Company, tells us how Cams achieved this success in a short time: “Our team of engineers and designers has an innate passion for innovation and we vendors never tire of testing them.

We work together to satisfy the customer and every new request is granted. We could say that Cams has never come out with two equal plants. Every customer, as well as every market, has a different need and we must satisfy it. The endless customization possibilities that Cams offers allow him continuous jumps of quality”.

The vision of Cams? The future is green! Yes, because if we have to pollute our planet to recycle the raw material, then all the work of the Company would be in vain. “At first, we study the environmental protection systems, then develop the machine so that it has the least possible environmental impact.

We have been on site and we must admit that it is a pleasure to spend the days outdoors listening to the buzz of the crushers and without breathing clouds of dust” – say the designers. Cams are equipped with noise abatement systems to keep them below 75 dB(A) and dusty emission abatement systems.

Another important aspect is the power supply to the machinery, all equipped with hybrid or electric power supply that allows to redistribute to the workplace the electricity they produce.

In addition, the low-speed rotation technology of the crushers’ shafts, as well as preserving the quality of recycled materials, requires very low fuel use and causes little wear of the components, significantly reducing maintenance costs.

What about 4.0 industry?

Finally, we asked Cams what approach the Company took to the technological evolution that has blossomed globally in the socalled 4.0 Industry. The software developers explained us how, through an electronic weighing system positioned on the unloading tapes of materials, they can detect the quantity of material produced and communicate the data to the Company servers through a PLC interconnected with them, optimizing in exemplary way the logistics of yard.

Thanks to the installation of GPS devices, they are also able to remotely control the systems and make the diagnostics even on machinery halfaway around the world.

“Our technicians travel all year around the world and can reach the customers in a short time, but knowing the problems before the arrival of our experts allows us to reach to the site prepared and already equipped with any necessary spare part, thus reducing the recovery time” concludes Andrea Trentini. A service to 360° is therefore what Cams offers.

Varia Costruzioni, a historical Company of public works in Tuscany

Varia Costruzioni was born in 1949, on the initiative of Onofrio Varia, and is now administered by the fourth generation of the family that has led the Company to develop itself thanks to the constant search for technological progress and the enhancement of the environment and primary and secondary resources.

The commitment in the industrial community is further marked by the figure of Stefano Varia, current President of ANCE Toscana Nord for the provinces of Lucca, Pistoia and Prato. In 2019, Varia Costruzioni celebrated its first 70 years of history.

Since 1949, the Company has established four production sites, one in near Lucca, in Montebonelli town, meant for the production of recycled aggregates, two between Lucca and Pietrasanta aimed at the recycling of milled asphalt and the production of bituminous conglomerate and one, operated by Varia Versilia Ambiente (VVA), which recycles 200,000 tons per year of construction and demolition waste.

Side by side in the quest of sustainability and circular economy ![]() Per la versione in Italiano: https://www.stradeeautostrade.it/materiali-e-inerti/fianco-a-fianco-nella-ricerca-di-uneconomia-circolare-e-sostenibile/

Per la versione in Italiano: https://www.stradeeautostrade.it/materiali-e-inerti/fianco-a-fianco-nella-ricerca-di-uneconomia-circolare-e-sostenibile/