The dawn of a new paver ![]() Per la versione in Italiano: https://www.stradeeautostrade.it/macchine-stradali/lalba-di-una-nuova-vibrofinitrice/

Per la versione in Italiano: https://www.stradeeautostrade.it/macchine-stradali/lalba-di-una-nuova-vibrofinitrice/

Rome was not built in a day… Yet CM Srl (http://www.cmsrl.com) has come a long way since 2017, which marked a turning point in its activity, boosted by the arrival of new entrepreneurial energies at the head of the Company.

Ever since it was established in 1974, CM found its vocation in contract works consisting in medium-heavy metalwork fabrication and in high-precision CNC machining.

Its wide fleet of machine tools and CNC machines on which the company has invested through the years, as well as the increasing specialization and accuracy of the provided works, made it become a first-choice supplier of the giants of the road, earthmoving, construction and automatic machine industry.

As a matter of fact, only a few companies can boast the ability to supply such complex metal parts as screeds, undercarriages and complete frames and can gain absolute trust from Italian and foreign customers.

Why not apply this practical know-how to the development of its own revolutionary paver? Though ambitious, this project is supported by a team of experienced designers of pavers who, throughout their career, have studied the requests of the workers in this sector without losing sight of the needs of a constantly evolving market.

The revolution of the small F175 paver

In 2019, the small wheeled F175 paver, completely manufactured at the CM’s headquarters in Conselice, in the province of Ravenna, entered this sector. Sidewalks, cycle paths, squares, holes on roads, trenches for pipelines and for optical fibre networks, safety systems in tunnels: all these interventions, requiring short spread width and having narrow working spaces, can now be carried out with the F175 paver quickly and with the greatest spread precision.

As a matter of fact, its compactness is surprising: its 258 cm of length and 80 cm of width allow it to pave in any jobsite limited by extremely narrow spaces. Thanks to its hydraulically controlled screed, it can spread from 80 to 135 cm whereas, with specific extensions and reductions, the spread can be extended up to 175 cm and reduced to 25 cm.

Its four wheels represent a key feature: two front tilting, steering wheels and two rear drive wheels give the F175 great stability during paving operations and transfers; this also prevents the machine from getting stuck in particularly rough jobsites (Figures 2 e 3 above).

Great attention is drawn to the comfort of the operator who, from his platform, can access the dashboard and adjust all the spread parameters, thickness included, by hydraulic controls (Figure 4 above).

While one operator can concentrate on driving and controlling the spread, only one operator more is necessary to run the skid loader for the material loading onto the hopper, eased by the hopper reclining wings widening the loading mouth. The same small skid loader can also transfer and load the F175 onto means of transportation not equipped with ramps.

Among the several objectives of the innovations applied to the F175, maintenance cost savings have a major importance: the smoothing plates of the vibrating screed, for example, are interchangeable and can be replaced individually at low expenses as they are manufactured inside CM’s plant.

To ensure the perfect material distribution along the screed, CM also installs its own patented system made up of independent augers-conveyor belt controlled by one single motor and by electro-mechanical clutches, making this machine as great as superior models.

The latest considerable achievement concerns safety: the F175 is also provided with the Road Circulation kit, soon on display at ASPHALTICA. Specific lights, a rear-view mirror and retroreflecting elements enable the operator to drive the machine safely, fully complying with the Italian Road Code.

CM certainly proves itself to be at the forefront of this subject since never before was it possible to transfer small pavers outside jobsite boundaries without using additional equipment (Figure 5 above).

When the going gets tough, CM lines the F220T up on the field

The second paver of the range, and the first tracked CM-branded model, was revealed to the public for the first time at BAUMA 2019, receiving widespread praise from the road sector professionals.

The 45 kW Perkins engine, installed since the starting of the F220T production, meets the European regulations about Stage V emissions standards and demonstrates that this paver has been further improved after its official introduction.

The F220T is ideal for wider jobsites than the F175: its hydraulically extendable spread width from 120 to 220 cm, that can be reduced to 0,5 m or further extended to 3 m by mechanical extensions and reductions, makes it perfect to pave multy-storey car parks, underground parking and underpasses, spaces between rails, roads inside and outside urban areas, emergency lanes, winding mountain roads, trenches, sidewalks and cycle paths.

A careful study on the power needed to supply all the machine services led to the choice of an engine perfectly proportionate to the current consumption of all the components, ensuring the lowest fuel consumption possible.

The reduction of fuel consumption and noise emissions can also be achieved thanks to a system adjusting the engine rotations automatically, with great benefits to the operator and the environment.

The panel control of the F220T provides the access to all the machine functions intuitively; a knob keeps the turning radius constant, so that the operator can concentrate on the screed spread.

In this model great attention is drawn to the safety of the operator and to anyone near the machine: the sensors monitoring the operator on the platform and stopping the machine in just a few moments in case of fall, as well as the side emergency stop buttons, comply with the european safety regulations (Figure 6 above).

Thanks to this, the F220T can boast the CE mark, just as all CM pavers. The possibility to choose different configurations of screed, i.e. with tamper and vibration system or with vibration system only, with electrical or gas heating, can satisfy the needs of any road construction Company and anywhere in the world (Figure 9).

Despite the technological applications, simplicity is predominant: the different screed configurations come from one single frame, enabling CM to quickly set the required version, but also letting dealers and workshops keep spare parts that are suitable for all configurations, involving remarkable management savings.

The choice to use many standard components, that can be easily found, speeds up any maintenance (Figures 7 e 8 above).

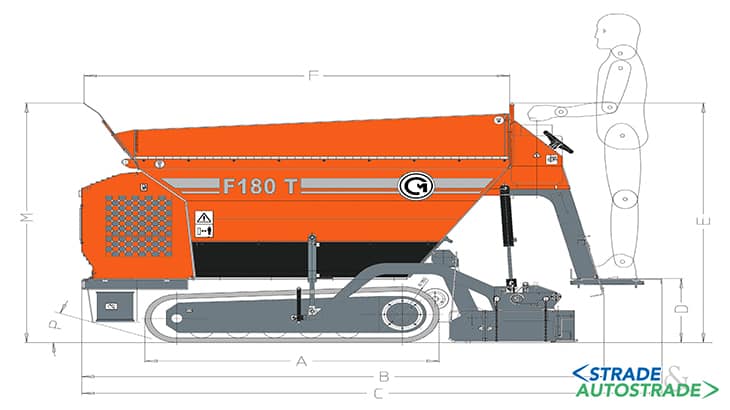

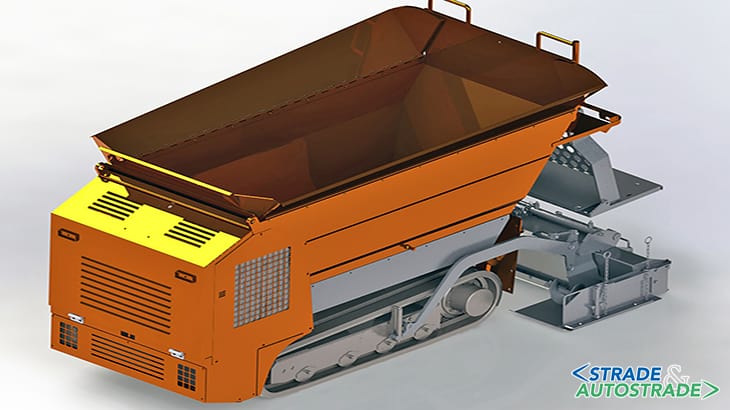

The star of ASPHALTICA: the new mini-tracked F180T paver

There is great expectation for this mini paver, born in the wake of its sister F175 and on which the ASPHALTICA spotlight will be focused.

Always compact, for narrow jobsites from 25 cm up to 180 cm, it is ready to face the most difficult challenges. No ground will hamper the spread of the F180T, whose tracks considerably increase the ground contact surface and thus improve traction.

This also enhances the screed flotation since the rubber tracks keep the paver in a more linear working position and, as a result, the flotation is excellent with materials of poor bearing capacity too (Figure 10 below).

The water-cooled, two-cylinder 10.5 kW Yanmar engine provides great power while maintaining a very low noise emission level. On the F180T, the transmission, the cooling system and the electrical power supply system of the various services are also upgraded, as well as the tank capacity: with a full tank capacity of 16 litres, the F180T offers a full day’s autonomy at work.

Ease of use is always an essential factor in the design of CM machines: as on the F220T, a potentiometer regulates the speed and an electronic knob adjusts the steering, a system that allows the F180T in ON or stand-by mode to maintain the set turning radius and the operator to check other functions (Figure 11).

The operator can pave in complete safety, constantly monitored by presence sensors; soon the road circulation kit for the F180T will be available too. “We have made great strides in these months” – says the CM paver designer at the head of the R&D team.

“Our Company, a small one with 70 employees, is proud to have launched – in just two years – three models of pavers with unique quality and easy to use. We look forward to presenting them during ASPHALTICA… an italian pride at the service of our roads”.

![]() Per la versione in Italiano: https://www.stradeeautostrade.it/macchine-stradali/lalba-di-una-nuova-vibrofinitrice/

Per la versione in Italiano: https://www.stradeeautostrade.it/macchine-stradali/lalba-di-una-nuova-vibrofinitrice/