![]() Per la versione in Italiano: https://www.stradeeautostrade.it/attrezzature-e-componenti/efficienza-compatta-la-soluzione-unica-per-il-riciclaggio-del-fresato/

Per la versione in Italiano: https://www.stradeeautostrade.it/attrezzature-e-componenti/efficienza-compatta-la-soluzione-unica-per-il-riciclaggio-del-fresato/

Two realities that meet in the wealth of technical and professional skills, in the historicity of know-how and in the choices of continuous innovation. One, Cams Srl (www.camssrl.it), is a world leader in the production of plants for the recycling of asphalt and conglomerate, the other, Marinelli Umberto Srl, is an efficient and dynamic organization that responds in a timely manner to the complexity of the road works sector in Abruzzo and Molise.

Enterprise, competence and dedication: three words to describe Marinelli Umberto Srl

Born in 1967 from the strong will of Marinelli Umberto that begins in his city of San Salvo his own activity, working on earth movement, excavations, stripping and road haulage. Today Marinelli Umberto Srl is a solid production reality for the entire neighbouring territory from Abruzzo to Molise.

The Company has been built over time, thanks to a process of evolution, continuous and constant improvement. A long journey made of small steps, by the far-sighted founder and owner Marinelli Umberto who, with skill and attention, has achieved success thanks to its solid and rooted culture of “doing”.

Mr. Marinelli has put professionalism and great willpower in the forefront to achieve the excellent results that he has achieved and that today form a consolidated reality.

With commitment and passion, Mr. Marinelli has combined tenacity, strength and leadership, the values of the family that now, represents his true strength and distinguishes the Company Marinelli Umberto Srl.

Cams, technology leader in asphalt recycling

Cams Srl was founded in 2001, inheriting 40 years of knowhow thanks to the acquisition of the TEM brand, producer of waste crushing plants since 1964. Always active in research and development and careful to meet the needs of the market with innovative solutions and exclusive patents, in recent years, Cams has dedicated part of its research to the sector of asphalt recycling.

The ability of Cams to capture the potential of the sector before the competition, gave the Company the opportunity to start a long-term project in collaboration with Alma Mater Studiorum – University of Bologna for the development of its own technologies, leading it today to be the world’s leading technology for asphalt recycling.

Among the latest technologies developed specifically for the treatment of asphalt was also born a secondary crusher, CTR 1200, with teeth specifically designed to create a high quality product while maintaining 100% of the bitumen contained in the recovered material.

In addition, Cams has internationally patented a system of mechanical fingers, the so-called pushers that allow introducing into the shredding mouth not only the milled but also the asphalt slabs.

Equipped with steel made knives on their ends, the task of the pushers is to reduce the plates dimensionally and to increase the holding capacity of the counter-rotating shafts, keeping the material inside the useful angle of the teeth, and allowing us to recycle even that part of the material that would otherwise end up in our unusable dumps.

Two realities, one vision

The famous British writer and traveller Bruce Chatwin made of a simple sentence his mantra: “The true house of man is not a house, it is the road”. What is more welcoming than walking on a new road in an uncontaminated landscape?

The Company Marinelli has chosen to recycle the asphalt for its works and Cams responded with its technology of excellence in this area, the Centauro 100.32 the compact and efficient hybrid machine of its range.

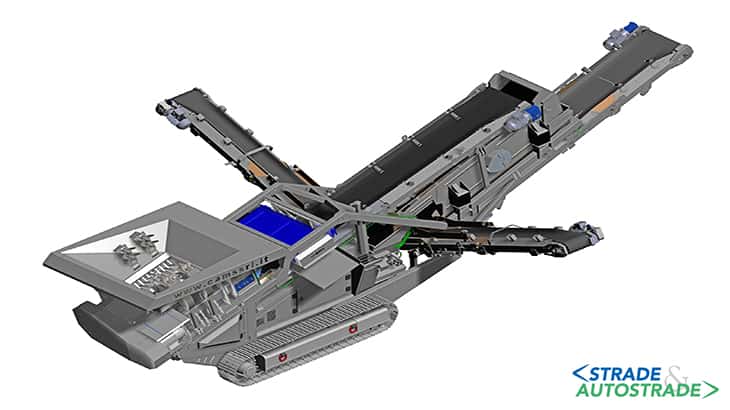

The combination of quality of the final product and respect for the environment led the Company Marinelli Umberto to choose the new Centauro 100.32, a compact unique machinery that carries on its crawler a crusher and a screen for complete use in the recycling cycle and that, equipped with hybrid motorization, has the minimum environmental impact.

Compact and easy to carry, in shape for road transport, can be used inside the recovery center or directly on site.

Centauro 100.32, shredder and screen in a single compact solution

Unlike traditional crushers used in recycling processes, the Cams FTR 1000 granulator installed on the Centauro 100.32 is equipped with two counter-rotating toothed shafts that operate at low rpm.

This process allows crushing by exploiting the shearing strength and thus optimizing energy consumption, while the low rpm significantly reduces wear and dust emissions compared to traditional technologies.

The crushing unit of this machine preserves the characteristics of the product without altering its grain size curve and without dispersing the bitumen contained in the incoming product, as verified by the tests carried out in collaboration with the laboratories of the Alma Mater Studiorum – University of Bologna.

Designed for maximum versatility, the compact FTR 1000 is equipped with two patented systems. The replacement of the shredder teeth is practical and fast. The interchangeable teeth allow replacing only the wear parts, keeping the body of each shaft in its seat and thus reducing maintenance costs.

The hydraulic adjustment system of the output size, managed directly by the operator through the remote control, changes the size of the material treated by the shredder in a fast and precise way.

The two-deck screen model CVV 032 with screening surface of 3,2 m2 each is designed to completely absorb the abundant amount of product leaving the primary crusher and thus optimize the production efficiency of the entire machinery.

Centauro has also been designed to be used as a shredder only. A bulkhead placed on the head of the screening unit allows bypassing the sorting function and obtaining a single finished product not calibrated.

Industry 4.0

Loyal to the innovative principles that characterize its history, Cams has adopted suitable measures to the technological evolution that on a global level has blossomed in the so-called Industry 4.0.

The software developers explained to us how, through an electronic weighing system installed on the material unloading belts, they are able to detect the amount of material produced and communicate the data to the business servers via a 4G connection.

The system keeps the site interconnected by optimizing in an exemplary way the site logistics that is constantly aware of the availability of materials and quantities processed for each CER code authorized to enter the plant.

In addition, thanks to the installation of GPS devices, you are able to control the systems remotely and also perform diagnostics on machinery from the other side of the world.

“We have technicians who travel all year round and can reach customers in a short time, but knowing before any problems allows us to arrive on the site prepared and already equipped with any spare parts needed reducing the maintenance time” – the Commercial Director, Andrea Trentini concludes.

![]() Per la versione in Italiano: https://www.stradeeautostrade.it/attrezzature-e-componenti/efficienza-compatta-la-soluzione-unica-per-il-riciclaggio-del-fresato/

Per la versione in Italiano: https://www.stradeeautostrade.it/attrezzature-e-componenti/efficienza-compatta-la-soluzione-unica-per-il-riciclaggio-del-fresato/