![]() Per la versione in Italiano: https://www.stradeeautostrade.it/ferrovie-e-metropolitane/il-monitoraggio-di-binari-ferroviari-con-la-tecnologia-wireless/

Per la versione in Italiano: https://www.stradeeautostrade.it/ferrovie-e-metropolitane/il-monitoraggio-di-binari-ferroviari-con-la-tecnologia-wireless/

A new approach

In the face of pressures associated with increasing traffic levels, safety concerns and a warming climate there is a need to monitor the behavior of rail track to measure and manage both short and long-term movement.

Thanks to Senceive wireless technology (https://www.senceive.com/), you can monitor a range of geometric track parameters in near real-time without having to visit site.

The list of geometric parameters includes track movement including cant, twist and longitudinal level; the same system can also incorporate sensors measuring environmental and structural parameters such as temperature and strain to help explain the cause of the movement.

Applications include measuring gradual long-term changes to inform asset management strategy, as well as more short-term changes such as those associated with slope movement, construction works or specialist interventions such as soil improvement.

Because the instruments are quick and simple to install and provide information to remote users for many years without re-visiting the site they are ideal where disruption to traffic is undesirable and where safety is a concern. Senceive technology allows the user to access data in near-realtime.

Wireless monitoring devices for railway trackbed

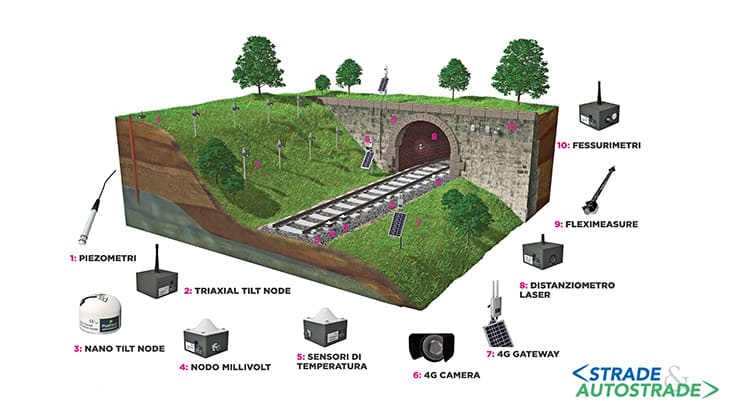

Wireless monitoring systems comprise three core elements: sensor nodes, a radio communications platform and an online data portal.

Senceive wireless solutions can include a wide range sensors. The most widely used are triaxial tilt sensor nodes which are designed to withstand high stresses. Using the Triaxial Tilt Sensor (High-G version) Senceive guarantees a product designed specifically for railway use, with a resolution of 0.0001° (0.0018 mm/m) and a repeatability of ±0.0025⁰ (± 0.0436 mm/m).

There’s also the new-generation NanoMacro; a compact tilt sensor that places precise, proven measurement technology in a more robust enclosure and offers increase user-interaction. The radio antenna is fully enclosed within the IP68-rated protective cover which will typically keep the instrument in use a decade after installation.

Where measurement of movement between two surfaces is needed, such as convergence of tunnel linings or bridge piers the Optical Displacement Sensors can be considered. This incorporates a laser distance meter and a tilt sensor widely used in tunnelling, excavations and construction.

Railways: FlatMesh™ & Intelligent Monitoring

Senceive offer a choice of radio communications platforms. FlatMesh™ is the natural choice for dense sensor deployments where rapid response time and network intelligent are critical. For widely dispersed deployments the longer-range LoRaWAN™ may be more appropriate.

FlatMesh™ combines high-frequency readings with very low power consumption whereas LoRa technology cannot provide high-frequency readings and requires 220V external power supply (or an external battery backup system).

The FlatMesh™ gateway can be powered by a 20 watt solar panel thanks to its internal rechargeable battery, which guarantees 15 days of lifetime (to cover external power failure). It can therefore be used a remote locations without depending on fixed power supply.

FlatMesh™ sensor nodes communicate via a highly robust mesh network. Data is transferred in a series of jumps to a cellular Gateway which relays data to the cloud. The maximum node-to-node distances is up to 300 m, and maximum read intervals is one second – performance that could not be achieved using the lower frequency LoRa platform.

FlatMesh™ can be configured to provide intelligent monitoring, for example increasing reporting frequency in the event of trigger levels being breached or automatically triggering a camera to send images of the site to Stakeholders.

This can detect objects as small as a football ball encroaching on the track, day or night. It can therefore provide valuable early warning of a landslide or an embankment failure to reduce danger and disruption on the railway.

Case study: monitoring of a railway in Italy

The site, with steep slopes and narrow valleys which do not help accessibility and solar power, has been equipped with a FlatMesh™ system with a gateway and 18 tilt sensor nodes at 3 m spacing, mounted on trackbed sleepers.

The user installed 18 IXH tilt sensor nodes and a cellular Gateway. The installation was extremely quick as it does not require special precautions, because tilt sensor has a range of ±90⁰.

Data monitored included track geometry (cant and twist) with reading intervals of one minute and alarms sent via email/sms.

Case study: consolidation works on railways

The FlatMesh™ system has also been successfully used in injection ground improvement works, carried by Uretek Services on high-speed Bologna-Rimini railway line.

Failure of railways embankments is becoming more common due to changing weather patterns and increasing traffic. Failures can cause settlement and gradual changes in track geometry, or more catastrophic voids and loss of support.

A new stabilization technique involves the use of expanding resins to improve foundation soils and reduce differential settlements. During the injection process, it is essential to monitor the behaviour of the trackbed to ensure that movement is within acceptable limits.

Senceive has supplied monitoring systems to successfully support these specialized works. The system allows the customer to have a user-friendly interface with trackbed cant, twist and longitudinal level data updated every 30 seconds and alarms transmitted in the event of values exceeding preset thresholds.

As you can see in Figure 4, 5 and 6, injections can firmly proceed even without interruption of circulation with a “real-time” control on geometrical parameters during the intervention. The installation of the sensors is rapid and does not require particular skills.

Engineers can then supervise works by relying on this wireless system, which allows to inform in a timely manner the achievement of pre-established alarm thresholds, with resolutions below 0.15mm on the level and a resolution of 0.04 mm / m on the twist.

This approach enables safer, smarter working, speeding up the remedial process and reducing disruption.

Why FlatMesh™?

In conclusion, Senceive offers the possibility to use both the long-range LoRa platform or the intelligent Flatmesh™ platform.

In many railway applications FlatMesh™ offers significant advantages. Because FlatMesh™ operates in a higher frequency part of the radio spectrum (2.4 Ghz compared to 868 MHz) it can handle the demands of dense sensor networks and can deliver data with minimal delay or lag time. It requires less power, offering battery life of 12 to 15 years, for example we can have two years lifetime with 1 minute reporting rate.

Flatmesh™ therefore allows high reporting rate, unlike LoRa where the data transmission is much more limited (due to a narrower band) and hardly going below 15min with many sensors connected.

![]() Per la versione in Italiano: https://www.stradeeautostrade.it/ferrovie-e-metropolitane/il-monitoraggio-di-binari-ferroviari-con-la-tecnologia-wireless/

Per la versione in Italiano: https://www.stradeeautostrade.it/ferrovie-e-metropolitane/il-monitoraggio-di-binari-ferroviari-con-la-tecnologia-wireless/