![]() Per la versione in Italiano: https://www.stradeeautostrade.it/ponti-e-viadotti/canakkale-bridge-un-simbolo-per-la-turchia-una-prodezza-per-lingegneria/

Per la versione in Italiano: https://www.stradeeautostrade.it/ponti-e-viadotti/canakkale-bridge-un-simbolo-per-la-turchia-una-prodezza-per-lingegneria/

Canakkale 1915: the name of the bridge; 318: the height of the two towers; 2023: the length in meters of the main span which in this way allows it to hold the record for the longest suspension bridge in the world; red and white: the colors used to cover the towers and the caisson.

These are the record numbers in a nutshell and let’s see why they become a symbol.

A bit of history…

On March 18, 1915 we witness, in the battle of Gallipoli (Çanakkale Savaşı in Turkish), the victory over the Triple Entente of the Ottoman naval forces, led by the then 34-year-old lieutenant colonel Mustafa Kemal Atatürk, who still today is considered as one of the events that gave rise to the birth of modern Turkey.

2023 is the expected date of the opening of the bridge and centenary of the Turkish Republic (1923-2023). White moon and star on a red background: these are the colors of the Turkish flag.

Already from these “magically” symbolic numbers it is clear that the new bridge under construction in Turkey over the Dardanelles cannot be just any bridge.

The first idea of building a bridge over the Dardanelles dates back to 1989; later, in 1995, however, its impracticability was declared due to the seismic problems of the region and the aerodynamic complications.

In 2010 the project was re-proposed within the program called “Turkey Vision 2023”, a massive development and investment program launched by Prime Minister Erdogan to make Turkey – on the occasion of its centenary – a modern nation and ambitiously projected to run as a candidate Bridgecountry between Europe and Asia through the construction of ports, airports, highways, hospitals, etc..

The bridge is part of the modern Kivali-Balikesir highway currently under construction, worth USD 4.7 billion, which will connect Eastern Thrace and Anatolia avoiding passing through the Istanbul junction, which has now become a megalopolis for over 15 million inhabitants! Currently, in fact, all the “land” connections between Asian and European Turkey pass through the Bosphorus where there are three bridges and a tunnel.

The Canakkale 1915 Bridge will cost USD 2.7 billion financed by 24 different Institutes from ten countries around the world and will have record numbers: the main span, with its 2.023 m will be the longest in the world and the suspended part will have a total length of 3.563 m (770+2023+770) which become 4.608 m also considering the two access ramps, respectively of 680 m and 365 m; the height of the towers of 318 m – like the Eiffel Tower – ranks sixth in the world among the tallest towers of suspension bridges!

The three lanes for each direction of travel run at a height of almost 70 m above sea level to allow the passage of the numerous merchant ships that cross the strait; the metal body, 3.5 m high and 45 m wide, has a split deck design to address and solve aerodynamic problems.

A specific structural system

Another undoubted problem that engineering has had to face is that of placing the bridge in a highly seismic area. In order to control the bridge’s response to the strong dynamic actions – that is, an earthquake with a 2.475-year return period – a specific structural system using special spherical bearings and unique hydraulic devices both supplied by FIP MEC (https://www.fipmec.it/) was devised and implemented for the suspended deck.

The bridge deck, supported by the cables over its entire length, is supported at the abutments by free sliding spherical bearings, allowing horizontal thermal movements up to ±1.525 mm along the longitudinal axis of the bridge.

The bearings resist compression loads of up to 22.000 kN and at the same time tension loads up to 6.800 kN thanks to their special anti-lifting system.

The transversal restraint of the bridge is implemented by eight lateral elastomeric bearings, arranged both at the abutments and at the towers, acting as elastic buffers for the bridge deck for all service and seismic transversal loads, up to 26.000 kN.

The main seismic protection system consists of eight special fluid dynamic dampers installed longitudinally between the suspended deck and the tower legs.

To add records to records, these dampers are arguably among the longest fluid dynamic earthquake protection devices ever built, possessing a pin-to-pin length of 9.1 m and reaching 10.35 m in their maximum extended configuration, with a weight of 17 t.

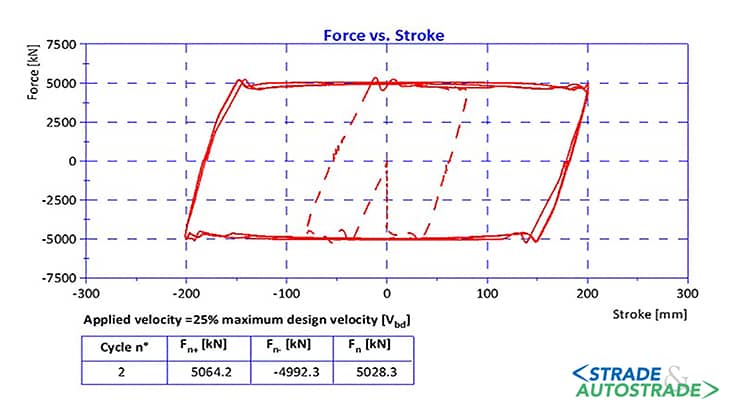

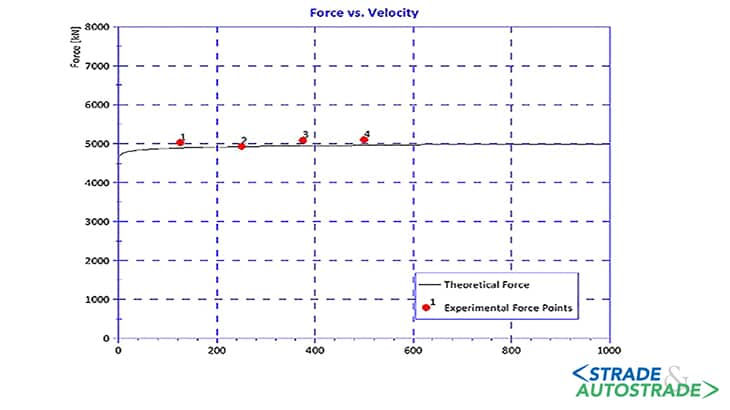

Fluid viscous dampers can be considered unique not only for their massive dimensions, but also for the particular type of restraint they provide. The seismic protection is given by limiting the force transferred to the piers, with a load capacity of 5.000 kN, reaching a maximum velocity of 1 m/s for the design earthquake condition.

In addition to the above, the dampers change the behavior of the bridge under normal service conditions. A rigid connection is ensured between the girder and the piers when forces of sudden onset, such as braking or wind, occur. In particular, a flow rate regulator hydraulically connects the two dampers on each position, ensuring an even load distribution on the structural elements.

At the same time, the thermal contraction/expansion movements of the bridge, as well as any other low velocity displacement, are accommodated without appreciable reaction. The above features are made possible by a special hydraulic configuration whose performance was accurately assessed by full-scale tests on one viscous damper for each type, which were conducted at FIP MEC’s test laboratory.

The support system is completed by eight special hydraulic endstop devices installed between the suspended deck and the tower legs: they limit the longitudinal movement of the deck to ±900 mm in order to avoid excessive movements of the bridge and protect the expansion joints from possible damage, since these have a limited movement capacity.

The hydraulic end-stop devices are axial devices comprising a piston-cylinder system able to resist a static maximum load of 13.500 kN and are among the largest hydraulic devices ever built for bridge applications, with a diameter greater than 1m and a total weight of 9 t. A special hydraulic connection between the endstops ensures an even load distribution on the structural elements.

Conclusions

The Canakkale 1915 Bridge project and its construction demonstrated the stubbornness of the government of Turkey and the skills of international engineering in accepting the structural challenges required by the desire for global connectivity as well as the high reliability of fluid viscous damper technology as effective solution for the seismic protection of bridges in areas of high seismicity.

It has also raised new challenges for the manufacturers of these devices, who were called upon to provide tailor-made solutions to the bridge designers and further enhance their production capabilities: technologically speaking, the Messina Strait Bridge may no longer be a mirage!

Technical data

- Contracting Authority: General Directorate of Highways (KGM)

- General Contractor: DLSY Joint Venture (DL E&C, Limak, Yapi Merkezi and SK Ecoplant)

- Final and executive project: Cowi A/S

- Supervisors: Parson and Tekfen Engineering

- Seismic protection devices suppliers: FIP MEC Srl

- Project cost: around 2,7 billion of Euro

- Duration of the works: 1.825 days

- Sumbmission date: according to project, 18 March 2023; to date, 18 March 2022

- Completion date foreseen: 18 March 2022

![]() Per la versione in Italiano: https://www.stradeeautostrade.it/ponti-e-viadotti/canakkale-bridge-un-simbolo-per-la-turchia-una-prodezza-per-lingegneria/

Per la versione in Italiano: https://www.stradeeautostrade.it/ponti-e-viadotti/canakkale-bridge-un-simbolo-per-la-turchia-una-prodezza-per-lingegneria/